The Challenge of Heating Large Aircraft Spaces

A 2,000 square foot hangar represents substantial volume—typically 20,000-30,000 cubic feet when you factor in ceiling heights of 12-16 feet needed for aircraft clearance. Heating that space efficiently while maintaining appropriate temperatures for aircraft storage creates challenges residential heating contractors rarely encounter.

Aircraft don’t need comfort heating like homes. But they benefit from temperature stability, humidity control, and protection from extreme cold that can damage engines, avionics, and composite structures. The question isn’t whether to heat your hangar—it’s how to do it cost-effectively while protecting your aviation investment.

Understanding Hangar Heating Requirements

What Temperature Do Aircraft Actually Need?

Aircraft storage doesn’t require 72°F year-round. Most general aviation aircraft tolerate wide temperature ranges without damage. But several factors make heating worthwhile:

Engine preservation: Repeated freeze-thaw cycles create condensation inside engines. Maintaining temperatures above freezing reduces internal corrosion significantly.

Battery health: Aircraft batteries, especially lithium batteries in modern avionics, degrade faster in extreme cold. Keeping hangars above 40°F extends battery life measurably.

Composite structures: Modern aircraft using composite materials can develop micro-cracks when repeatedly cycled through freezing temperatures. Maintaining stable temperatures above freezing protects structural integrity.

Working conditions: Maintenance work in 20°F hangars is miserable and inefficient. Even moderate heating to 50-55°F makes hangar work viable during winter months.

Most hangar owners target 45-55°F for storage and 60-65°F when actively working on aircraft—much lower than residential heating standards but sufficient for aircraft protection and human comfort during work periods.

Insulation Determines Heating Costs

Uninsulated metal hangars leak heat ferociously. A 2,000 sq ft uninsulated hangar in Minnesota might require 200,000+ BTU/hour to maintain 50°F in January—that’s furnace capacity approaching small commercial buildings.

Insulated hangars with R-19 walls and R-30+ ceilings might need only 60,000-80,000 BTU/hour for the same conditions. The insulation cost difference ($8,000-15,000 for spray foam or rigid panels) pays back in 3-5 heating seasons through fuel savings.

If you’re building a hangar, insulate during construction. If you’re renting or buying an existing uninsulated hangar, adding insulation may still be cost-effective depending on fuel costs and heating season length.

Heating System Options for Hangars

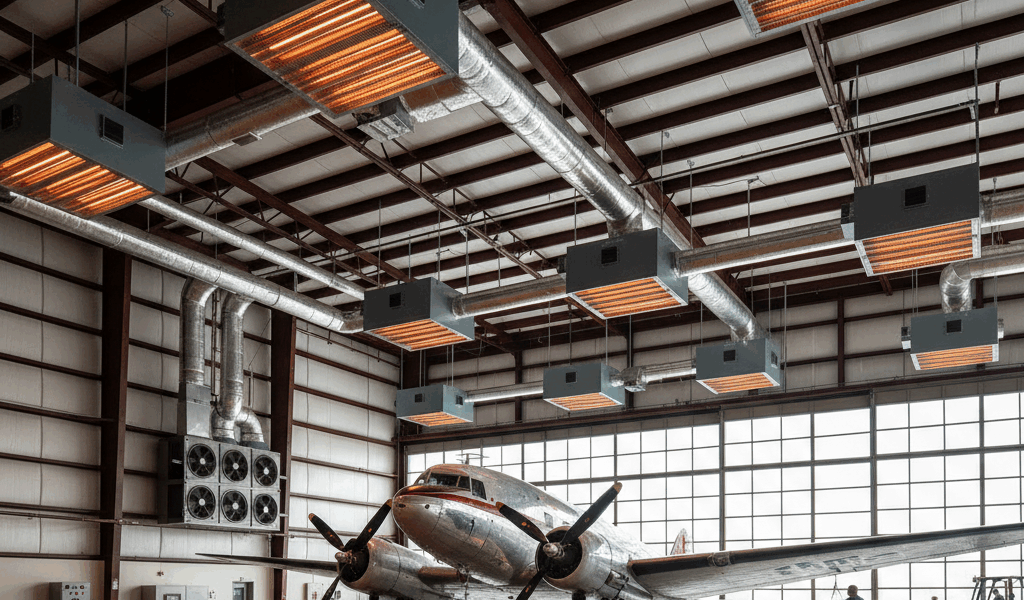

Radiant Tube Heaters: The Hangar Standard

Radiant tube heaters mounted in hangar ceilings heat objects and floors rather than air. This makes them exceptionally efficient for high-ceiling spaces where heated air rises and wastes energy.

U-tube or straight tube configurations mount 10-14 feet high, using propane or natural gas burners to heat metal tubes to 600-900°F. The tubes radiate infrared heat downward, warming aircraft, floors, and occupants directly.

For a 2,000 sq ft hangar with 14-foot ceilings, expect to need 2-3 radiant tubes rated at 30,000-50,000 BTU each. Total system cost installed: $6,000-12,000.

Advantages: Low operating costs, effective in drafty spaces, heats quickly when needed, minimal floor space used

Disadvantages: High initial cost, requires professional installation, doesn’t provide even temperature (floors get warmest), requires fuel line installation

Forced Air Unit Heaters

Cabinet-mounted gas-fired unit heaters blow heated air into hangars using fans. They’re less expensive than radiant systems initially but less efficient in high-ceiling spaces.

Typical installation uses 1-2 heaters rated 75,000-125,000 BTU mounted on walls at 10-12 foot heights. Fans distribute heat, creating more uniform temperatures than radiant systems.

For a 2,000 sq ft hangar: $3,000-6,000 installed

Advantages: Lower initial cost, faster temperature rise, more even heating, easier DIY-friendly installation

Disadvantages: Higher operating costs (heating air vs. objects), stratification in tall spaces, noisy when operating, ductwork may be needed

Wood/Pellet Stoves: The Budget Option

A large wood or pellet stove can heat 2,000 sq ft if you’re willing to manage fuel and operate it manually. Commercial hangar stoves designed for large spaces burn wood or pellets, producing 100,000-150,000 BTU.

Cost: $2,000-4,000 for stove plus $1,000-2,000 for installation (chimney, hearth pad, clearances)

Advantages: Very low fuel costs if you have wood access, no utility hookups needed, heat during power outages, backup heat source

Disadvantages: Requires manual fueling, can’t maintain temperature automatically, insurance may increase, clearances take floor space, requires frequent ash removal

Wood/pellet heat works best as supplemental heat or for hangars you occupy frequently enough to manage firing. For unattended background heating maintaining minimum temperatures, automated systems work better.

Electric Heaters: Simple but Expensive

Electric unit heaters provide the simplest installation—just mount and plug in (or wire in for large units). But operating costs in most markets make electric heat expensive for continuous use.

Heating a 2,000 sq ft hangar to 50°F in winter weather might require 15-20 kW continuously. At $0.12/kWh, that’s $3.00/hour or $2,000+ per month for round-the-clock heating.

Electric heat makes sense for supplemental heating during work periods or in mild climates where heating demand is occasional rather than continuous.

Heat Pumps: The Efficiency Option

Mini-split heat pumps provide 2-3 times the heat output per unit of electricity compared to resistance heaters. A 48,000 BTU mini-split system can heat 2,000 sq ft in moderate climates.

Cold climate heat pumps function effectively to 5°F or lower, making them viable even in northern states. Multiple indoor units provide zone control.

Cost for 2,000 sq ft coverage: $8,000-15,000 installed

Advantages: Low operating costs, provides summer cooling, highly efficient, quiet operation

Disadvantages: High initial cost, reduced output in extreme cold, requires electrical service upgrade sometimes, outdoor units need mounting space

Fuel Type Considerations

Natural Gas: Lowest Operating Cost

If natural gas service reaches your hangar, it provides the lowest cost per BTU in most markets. Gas radiant heaters or unit heaters connect to utility lines, requiring no tank fills or fuel delivery.

Operating cost example: Heating 2,000 sq ft to 50°F in Zone 5 climate uses approximately 60,000 BTU/hour average (factoring in cycling). At $1.20/therm (100,000 BTU), that’s $0.72/hour or $520/month for continuous heating.

Propane: Flexible but Costlier

Propane works anywhere, not just where utilities run. Large tanks (500-1,000 gallon) store enough fuel for full heating seasons.

Propane costs roughly 2x natural gas per BTU in most markets. The same 60,000 BTU/hour heating load costs approximately $1.40/hour or $1,000/month.

Tank rental or purchase: $50-100/month rental for 500+ gallon tanks, or $1,500-3,000 purchase

Electricity: Convenient but Expensive

As calculated above, electric resistance heat costs $2,000+/month for full-time use in cold climates. Heat pumps reduce this to $700-1,000/month in moderate climates, competitive with propane.

Control Strategies to Reduce Costs

Setback Thermostats Save Substantially

Maintaining 55°F continuously costs far more than maintaining 45°F during unoccupied periods and boosting to 60°F before working.

A setback thermostat programmed for 45°F storage temperature and 60°F during scheduled work periods can reduce fuel consumption 30-40% compared to constant temperature operation.

Smart thermostats with mobile control allow you to trigger heat boost remotely before arriving at the hangar, so spaces reach comfortable temperatures by the time you arrive.

Zone Control for Large Hangars

If your 2,000 sq ft hangar separates into aircraft storage and workshop areas, heating both spaces equally wastes fuel. Zone control maintains different temperatures in different areas.

Maintain 45°F in aircraft storage areas and 65°F in workshop zones only when working. This typically reduces overall fuel costs 20-30%.

Destratification Fans Improve Efficiency

Heat rises. In 14-16 foot ceilings, temperature differences of 15-20°F between floor and ceiling are common. Slow-moving destratification fans mounted in ceilings push warm air back down, improving comfort and reducing fuel waste.

Cost: $300-600 per fan; most 2,000 sq ft hangars need 1-2 fans

Fuel savings: 10-15% in high-ceiling spaces

Sizing Heating Systems Correctly

Online BTU calculators provide starting estimates, but hangar heating calculations require professional attention to:

– Ceiling heights (dramatically affect heat loss)

– Door sizes and usage frequency (huge heat loss during opening)

– Insulation levels

– Desired temperature rise above outdoor conditions

– Climate zone and design temperatures

– Air exchange rates

A properly designed system maintains desired temperatures during design weather (e.g., 0°F outdoor in Chicago) without oversizing that wastes money upfront and reduces efficiency.

Rule of thumb for insulated hangars: 30-40 BTU per square foot

Rule of thumb for uninsulated hangars: 60-80 BTU per square foot

These are approximations—get professional heat loss calculations before purchasing equipment.

Installation Considerations

Permits and Codes

Gas-fired heating systems require permits and inspection in most jurisdictions. DIY installation of gas equipment violates codes and creates insurance issues.

Licensed HVAC contractors ensure proper combustion air, venting, gas line sizing, and safety controls. Insurance companies may deny claims if fires or carbon monoxide incidents involve unpermitted gas installations.

Combustion Air Requirements

Gas heaters consume air for combustion. Sealed, tight hangars need dedicated combustion air supply or the heaters will backdraft, producing dangerous carbon monoxide.

Modern direct-vent heaters draw combustion air from outdoors through dedicated vents, avoiding indoor air quality issues. This costs more initially but provides safer operation.

Fuel Line Sizing

Undersized gas or propane lines cause pressure drops that reduce heater output and create safety issues. For a 100,000 BTU heater system, expect 3/4″ to 1″ gas lines depending on run length.

Propane tank sizing: For 100,000 BTU total heating capacity, minimum 500-gallon tank. Larger tanks (1,000 gallon) reduce fill frequency and provide better pricing.

Making the Right Choice for Your Hangar

For most owners of 2,000 sq ft hangars used regularly year-round, insulated construction plus natural gas or propane radiant tube heating provides the best balance of comfort, aircraft protection, and operating economy.

If budget is tight initially, insulate first and use portable propane or electric heaters temporarily. Add permanent systems as finances allow.

If you’re in the hangar sporadically (weekend flyers only), setback thermostats maintaining 40-45°F with manual boost to 60-65°F when working provides aircraft protection without excessive fuel costs.

Whatever system you choose, proper sizing, professional installation, and smart controls make the difference between manageable heating costs and budget-busting fuel bills. Your aircraft deserves protection from temperature extremes—but protecting it doesn’t require heating like a house.